Among avid cyclists, it is difficult to surprise anyone with a technical feat. A bicycle with a trimmer engine would have long ago ceased to be the greatest invention of mankind. This unit has found its admirers in small towns and villages, where no one is confused by the high speed of the cyclist and the noise made by his transport. The result of garage conversions is actively gaining the popularity of riders, and for good reason.

Advantages of bicycles with a motor from a trimmer

Such hybrids have a range of positive qualities that fans of practical solutions will certainly appreciate:

- quickly gain great speed;

- electric motors work from the current, which can be created with a trimmer (it is practical, convenient and does not harm the environment);

- installation of the power mechanism does not greatly affect the change in size of the bike – it remains the same compact and maneuverable, which is important for city streets at rush hour;

- are characterized by endurance and the ability to cover long distances;

- versatility (a bicycle with a motor from a trimmer is easy to repair, and all the necessary parts can be purchased in specialized stores);

- easy care (it is enough to clean the power unit from dust, dirt and moisture);

- the trimmer is easy to remove, so you can return the original appearance of the bike;

- ergonomic (such a unit will not take much space, so you can store it even in a city apartment).

Let’s not twist our hearts and admit that the disadvantages of this equipment are. First of all, this is a specific sound, which not everyone will like. However garage masters learned how to connect power unit competently and as a result this disadvantage is reduced to a minimum.

It remains only to understand how to make a bicycle with a motor from a trimmer with your own hands. Let’s say at once, it will have to tinker a little, but the result is worth it.

List of materials and tools

We will offer a primitive list of necessary elements, and you only depending on the desired result will adjust it. You should start with the choice of suitable “raw materials” – it is the motor and the bike on which it will be installed. Other tools and materials that may be useful in the work:

- motor with a drive;

- gearbox;

- brakes;

- welding machine;

- grinder;

- a set of nuts and bolts;

- wrench set;

- a set of wrenches; a set of wrenches; a set of sprockets;

- gas handles;

- steel tubes and plates.

When you have gathered all the necessary components around, you can get to work. But first you need to get acquainted with the theoretical aspects, so you can imagine what the process should look like in practice.

Step by step instructions on the construction of a bicycle with a trimmer engine with your own hands

So, you have decided to modernize your bike. How to make a bicycle with an engine from a trimmer? Any supernatural efforts are not needed, but accuracy and patience will definitely be useful to you. Let’s start with the simplest thing, choosing the right motor, because it will determine the final result.

The choice of engine

Before you start retrofitting the bike, you need to choose a suitable motor. He can be:

- gasoline;

- electric.

The first is good in that it does not require a battery to work, that is, the bike is not tied to the power grid. It is worth paying attention to the power units of medium power (up to 2 horsepower). Suitable two-stroke motor – this is the most common type of engine. If you are lucky and have the opportunity, you can buy a four-stroke engine – it is not as loud noise, and its “appetite” is much lower.

Electric motors can not boast high power, so it makes sense to choose a model with an indicator not more than 1.2 kW. Without recharging the electric motor will be able to work a maximum of 2 hours, so you have a shortage of time, as at Cinderella. Otherwise you will have to go back, twisting pedals “pumpkin”.

So decide what you need an advanced bicycle, and then choose a motor for it. Advice from experienced owners – take a motor from a gasoline trimmer. It is ideal because it has a convenient design for installation. In addition, the motor already has a centrifugal clutch, which allows the engine to run at idle speed, that is, the bike is rolling.

To begin with, it is necessary to trim the nose of the motor, where the operating shaft is located. This is necessary in order to later install the drive sprocket. Most models have a plastic body, so you can easily cope with the task, using a grinder.

Installing the drive sprocket

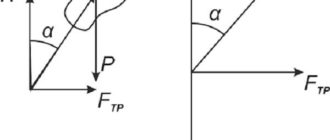

The drive sprocket needs to be attached to the motor shaft. To be more precise – on the clutch shaft. The sprocket should be as small as possible, since the speed of such a motor is quite high, and we need to get the optimal torque.

To put the pinion, you should grind the gear shaft a little bit with a grinder, and then the star can be put on the shaft with minimal clearance. The sprocket should now be welded.

Installing the sprocket

The part from the drum brake, which is screwed on the hub of the wheel, will come in handy. It is to it that we will weld the pinion. It should be big enough to reduce the wheel revolutions, converting them to high torque.

To do this, center the part with bolts and nuts, and then weld the pieces together. You can attach the sprocket to the spokes for greater reliability. At the very end, the sprocket should be painted to make it look nice and become resistant to corrosion.

Installing the chain

Before proceeding to this step, you should at least fix the engine a little bit. You can make a temporary fixture from a piece of steel tube and some plates. One side of the fastener should be secured with a nut to the wheel axle and the other side with a screw to the motor.

When the motor is secured, prepare the chain. First you need to calibrate its length by removing or adding links. You can make the chain on locks, or you can assemble a single piece if you have a tool on hand to press out the connecting pins.

Fixing the Motor Securely

The motor should be secured, as they say, with care. It is in your own interest. The best option – to make special fasteners from steel pipes and plates, which are screwed to the “native” bolts of the engine. The fasteners are fixed to the frame by the rear wheel axle and to the fork with self-tapping screws. All in all, it should be quite a reliable construction. It remains only to degrease the surface and cover it with paint to prevent rusting.

Now you can start the motor and see how everything works. Pay attention to how the chain behaves – it shouldn’t rock and wobble. Otherwise it might come off and hit the spokes of the rear wheel, which can lead to very unfortunate consequences.

Steering

On a steering wheel we put a handle of control of a throttle. You can pick up a handy model designed for mopeds. The cable goes along the frame and connect it to the engine throttle. It is also necessary to connect the ignition – this is necessary in order to turn off the engine if something goes wrong. The throttle knob is connected to the motor by means of a cable.

Be sure to install the brakes. It is desirable to use a pair of brake discs, which are put on the leading and trailing wheels. To control them, you should connect cables to the levers. Brakes must be serviceable and work flawlessly, as motorized bicycles a priori develop greater speed.

Testing a homemade bike with a trimmer motor

The basic work is done – you can start testing. If the engine is new or there have been no problems with it before – the launch should be successful. To extend the life of this unit, you should be guided by the following recommendations:

- Timely replacement of consumable elements (the same air filter should be changed regularly – otherwise some mechanisms and units will begin to work with increased load).

- Use of quality fuel and engine oil in the correct ratio.

- Regular lubrication of the gearbox.

- Prevention of excessive heating of the engine.

In addition, you need to pay more attention to the rubber to make it safe to use the bike.

Conclusion

Using an upgraded bike, keep in mind that it is undesirable to carry too heavy a load on it, because this can lead to overheating of the engine. But in general, such a design is very practical. A motorized bike allows you to overcome long distances and periodically give your legs a rest. Such equipment is suitable for villagers and dacha owners, who often have to transport vegetables, fruits and other cargo. If you set the motor competently, you can ride such a bike in the city, deftly maneuvering between the rows of cars standing in traffic jams.

This article is great for those interested in creating their own bike with a trimmer engine! It’s amazing to see how the author was able to craft such an innovative design from scratch. Great job!