Hydraulic brakes are most often used where high precision, fail-safe operation, reaction speed and reliability are important. This applies above all to massive bikes that conquer mountain peaks and steep hills. Hydraulic brakes have also settled in the design of speed bikes, as they allow you to accurately and quickly reset the speed when needed.

Today we will tell you in more detail about the mechanism and the principle of operation of hydraulic brakes, learn their strengths and weaknesses, as well as designate the best models of mechanisms and their varieties.

The principle of hydraulic brakes

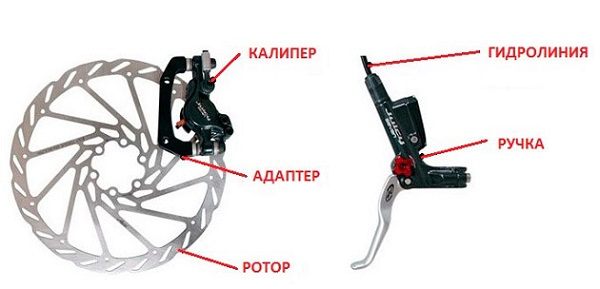

The mechanism of action of hydraulics is largely similar to mechanics. The purpose is the same – to stop the bicycle. However, there are significant differences between them. In particular, to transmit the force to the brake pads in the hydraulic instead of cables use a hydraulic line – it connects the brake handles to the stopping mechanism of the bike. The latter can be disc, rim or hydraulic. The main components include:

- The brake handle, which is located on the handlebars. In turn, it consists of a lever to transmit the force, a piston to which this force is transmitted and a cylinder that pushes the fluid through the hydraulic line.

- The hydraulic line, or hydraulic line, is represented by a tube extending from the handlebar to the caliper.

- The caliper is the device that receives the force transmitted through the hydraulic line and transmits it to the cylinders with pistons.

The hydraulic line is filled with a special fluid or oil – the substance is pressurized in a constant aggregate state. As soon as the brake lever is depressed, the brake cylinder displaces the fluid from the system, which in turn actuates the slave cylinder mounted on the frame or fork of the bicycle. The slave cylinder actuates a piston and brake pads that lock the wheel with the disc.

Hydraulic brakes are a sealed circuit. Otherwise, they simply will not perform their function. The fluid that fills the hydraulic line does not compress or stretch, that is, it remains in an inert state, which is what makes the hydraulics work.

That’s the whole mechanism. When servicing and during brake repairs, you should keep in mind that the fluid with which the hydraulic line is filled is toxic and can provoke serious poisoning. Moreover, even if it comes into contact with plastic elements or paintwork, damage is possible.

Pros and cons

High accuracy and speed of reaction – two obvious advantages of hydraulic brakes. It is thanks to these qualities, this mechanism for stopping the vehicle has become so widespread. The advantages of hydraulics do not end there. The following qualities can be attributed to the pluses:

- Reliability and endurance. The latter quality played not the least role in the transfer of hydraulics on the bike. As for reliability, the hydraulic braking system has shown itself in all its glory over the years of its use on cars. With proper care, hydraulic brakes in practice prove to be several times more reliable than mechanics. The honed sense of proportion allows you to control the braking system with jewel-like precision, which is extremely important in extreme riding.

- Braking power and responsiveness. Hydraulic characteristics result in high levels of braking force with very little force applied. One or two fingers are enough to stop, and the braking force can be so strong that it can be compared to a stopcock.

- Modulation or moderate progression of braking force. You can press the brake knob sharply and hard all the way down, wiping out all the tires. Or you can apply the brakes gently and smoothly, controlling the stopping force.

Among other things, the advantages of hydraulics can be attributed to the durability, due to the minimum probability of breaking the cables. The system of hydraulic brakes is maximally closed from the external environment, which ensures its durability and serviceability.

As for the disadvantages – they are there, and sometimes the disadvantages are a significant factor that plays into the counterbalance. First of all, it should be noted the cost: if you compare two absolutely identical bikes, but with different brakes (mechanics and hydraulics), the latter will be significantly more expensive.

The complexity of maintenance is another nuance that negatively affects the reputation of an effective braking system. The mechanism requires a clear knowledge of all its nodes and components. Not every cyclist will be able to rebuild the brakes themselves and make repairs.

Brake tubes and hoses are quite vulnerable elements of the system, a breakdown of which in the field can radically correct the plans of the rider. Hydraulics is an extremely finicky mechanism. Poor-quality brake fluid can fail absolutely all mechanisms of brakes. As for the rest of the disadvantages, they are represented by the following moments:

- significant weight of the construction;

- inconvenience when mounting the wheels;

- the probability of leakage.

Traditionally, hydraulic brakes are used in tandem with disc devices, so it is worth outlining some nuances.

Varieties of hydraulic disc brakes

Disc brakes differ from rim brakes in that the bicycle is stopped by clamping the brake disc, which is rigidly fixed in the hub by the brake pads, fixed at the back on the frame and at the front on the fork jaws.

The design of the brake cylinder can vary, so hydraulic brakes are divided into the following types:

- single-piston (only 1 pad is involved, budget devices, rarely used in practice);

- double-piston (with opposed or floating pistons)

- multipistors (quite capacious and strong constructions which are mounted on bikes for freeride and downhill more often).

Two-piston systems with opposed pistons are the most common. There are also single-piston systems, but they are inferior to twin-piston ones. Complex multi-piston devices are found in bikes for downhill, where the important power, and simplicity of design takes second place.

Hydraulic disc brake – this is the apotheosis of reliability. But the complexity of its repair (especially in the field) is often a discouraging factor. At the same time, it is impossible not to note the wear resistance of the braking system – you will have to sweat a lot to bring it to the state of coma.

Are there differences between hydraulics and mechanics?

Certainly, there are differences, and they consist not only in the name. The mechanical system transmits power via a cable, while the hydraulic system transmits it via pipes filled with brake fluid or oil. Experienced riders note other features of the hydraulic system that give it an advantage over the mechanical one:

- No need for frequent brake adjustments;

- tangible reduction in braking distance;

- the hydraulics are much better to cope with off-road conditions;

- high power.

Choosing one or another braking system, you need to consider the specifics of riding, riding style and personal preferences. If an ordinary cyclist is enough reliable mechanics, then fans of extreme preference should give preference to a hydraulic braking system.

The best hydraulic brakes on a bicycle

To date, manufacturers of braking systems for bicycles can fully satisfy even the most demanding consumers. Cheap and gray? Get the mechanics! Need something more efficient and reliable, like an automatic Kalashnikov? Pay attention to hydraulics. By the way, recently it began to appear in the average price category, so the true fans of cycling can find the right equipment for their iron horse.

Clim 8 Clark’s.

It is clear that in this diversity to an inexperienced cyclist will be difficult to understand, so we have prepared a brief guide to the best firms-manufacturers:

- Shimano. The brand has long been clearly associated with bicycles and their components. The company produces reliable brakes, including hydraulic brakes. Recently, the firm has updated the Deore line, improving the already crisp operation of the cylinder. If funds allow (a complete set will cost about 5-7 thousand rubles), you can buy Shimano Deore – a hydraulic braking system with excellent responsiveness and reliability.

- Clim 8 Clark’s. Budget option, adapted to work in different weather conditions. This is a full-fledged multi-cylinder brake. The design of handles can embarrass a little, but this nuance is more than compensated by the beauty of kevlar-reinforced hydraulic hoses.

Cheap hydraulics are a dubious bargain. The way our life is arranged, the worthy quality demands the corresponding payment.

Care Recommendations

Bicycle brakes need regular inspection and maintenance. Especially if the bike is often operated in adverse conditions. On your own to fix the hydraulics in the absence of experience and skills is definitely not worth it – it is better to entrust this matter to a specialist. In addition, it should be borne in mind that the brake fluid discussed system is extremely toxic – its contact with the skin can cause burns.

Experienced owners and repairmen give some important tips to prolong the life of the brake mechanism:

- Keep an eye on the condition of your brakes. Dirt is enemy number one. Therefore, after riding on forest trails or in the rain, you need to thoroughly clean the system and dry it.

- The rotor should be cleaned with a special cleaner.

- Regularly check the tightness of bolts and fasteners.

- Check hydraulic lines and mechanisms for leaks.

In any case, timely diagnostics allows avoiding a number of much more serious problems. If you can not assess the condition of the brakes, take your bike to the nearest workshop. It’s enough to do a comprehensive maintenance once every 6 months. If you do diagnostics at the beginning of the season and at the end of the season, your bike will serve you for a long time.

Conclusion

Hydraulic brakes are by far the most effective and reliable devices that provide proper safety. Mechanisms can not be attributed to the budget category of parts, but their functionality is at a high level.

Squeaking brakes – then lubricate or replace, because they are still subject to replacement and for safe operation, so on such things at all should not save, I think

Great article! Hydraulic bicycle brakes are a great innovation for cyclists. They provide superior stopping power and control compared to traditional rim brakes. It’s great to see the principle of operation explained in detail with recommendations on how to properly maintain them. Thanks for the helpful information!