Reliable brakes are not only important to professional athletes, but also to the average person who likes to ride on a Sunday afternoon in a nearby park. The existing varieties of braking systems are able to meet the requirements of any, even the most demanding cyclist. However, hydraulics are the most popular. Pumping of hydraulic bicycle brakes is necessary after repair or replacement of the mechanism.

Signs of breakage

The very first and most obvious sign of failure is the fact that the system begins to brake itself. This is explained by air entering the mechanism. This can happen after a fall, due to an insufficient amount of brake fluid in the tank or if the hydraulic line is disconnected.

Even from school physics lessons we know that air can be compressed. And when air enters the system, it acts like a spring. The hydraulics can malfunction if the operating piston jams. This can happen after riding in high humidity conditions.

Another reason that necessitates urgent repair is that the brake handle has lost its elasticity or does not respond at all to the driver’s command.

Design and Diagnostics

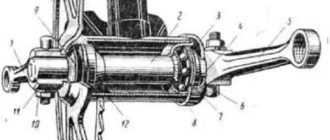

At the minimum, the hydraulics consist of a cylinder-piston group, which is connected by a hose with a pressurized fluid. When the brake handle is pressed, the piston displaces the fluid or oil from the master cylinder and directs it to the operating cylinder, which is in the machine. And here is where the pressure causes the pistons to extend and begin to exert pressure on the brake pads. When the latter begin to rub against the rotor, the vehicle slows down and stops.

In order to understand what exactly caused the problem, you need to perform a number of manipulations:

- Remove the wheel where the malfunction appeared.

- Thoroughly clean the brake machine (best to do this with an old toothbrush).

- Remove the pads.

- Press the service pistons in with a screwdriver, then gently press the brake handle.

- Ideally, both pistons should extend forward.

- If one is jammed, you will need to use the repair kit.

It is recommended to carefully inspect the brake system for leaks. If they will be found, then the group of cylinders and pistons requires replacement. It will not be superfluous to inspect and the hydraulic line – it should not be kinked and have signs of damage.

Necessary tools

Pumping of the hydraulic brake can take place by different methods. To implement one of them, the following tools will be needed:

- a transparent tube;

- 2 200 ml syringes;

- hexagon;

- oil or brake fluid (depending on the requirements of the specific system);

- dry and clean rags for wiping dirt.

Caution. Use caution when servicing hydraulic brakes. The fluid required for the system is extremely toxic.

Instructions

The procedure is as follows:

- Remove the top bolt on the brake lever and move it 10 degrees up to keep the fluid from leaking out of the cylinder.

- Take out the o-ring.

- Insert a tube with a syringe or other container into the hole. This is necessary to allow the fluid or oil to flow out.

- Fill another syringe with brake fluid or oil, and then bleed off any excess air.

- Attach the tube tightly to the nozzle.

- Loosen the pumping bolt, then slowly squeeze in the contents of the syringe.

- Return the bolt to its original position.

- Remove the tube and syringe.

While pumping, you should periodically tap the hydraulic line in different places to get excess air out of the system.

Safety precautions

We have already said that the brake fluid is toxic, so all manipulations should be performed with caution. Take into account that for each model of bike is designed for a certain liquid or oil, so it is extremely undesirable to mix compositions.

Conclusion

Hydraulic brakes – a relatively complex mechanism of the bicycle, which requires to itself the utmost care. Pumping the hydraulics is necessary in the course of making repairs or replacing directly the entire system.